ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

These rollers utilise a new articulation joint that enables quick drum adjustment from in-line to off-set configurations, which is helpful when working close to obstructions.

When the machine is off-set, operators need watch only one drum, knowing the second will be a safe distance from the obstacle. The in-line drum setting is available when it´s time for productivity in open spaces. All these features make the machines great fits for rental companies.

Ready to learn more? Click on the product hotspots or the chat contact.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

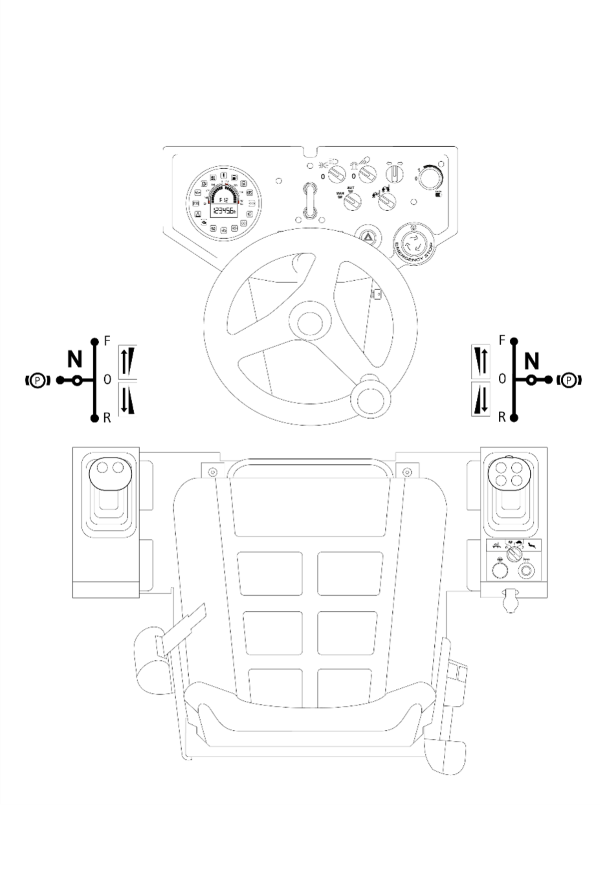

Operator station

A rubber-mounted platform limits the vibration that reaches the operator and enables comfort throughout the shift.

INTUITIVE DASHBOARD

- Clear and logical layout

- Reliable, intuitive switches

- Integrated multifunctional display

ADVANCED FUNCTIONS

- Panic stop function

- Loading, working, transport modes

- Integrated parking brake

- Automatic engine speed setting (only Stage V / Tier 4 models)

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Vibratory system

Great combination of high-performance output and maintenance-free vibratory system make the machine more productive and cost effective.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Sprinkling system

Exceptional water tank capacities on all lines extends working intervals between fillings. A multilevel filtration system lengthens sprinkler life.

- ARX line 2.1-2: 190 liter (50.2 gal)

- ARX line 2-2: 190 liter (50.2 gal)

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Articulation/oscillation joint

This maintenance-free joint provides wide turning angles and enables switches between in-line and off-set configurations. This is a great feature for rental fleets.

The central steering joint with integrated oscillation connects key components and ensures balanced machine weight distribution and consistent ground contact.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Serviceability

A wide-opening hood provides excellent access to the engine compartment and daily inspection points while also offering a quick overview of fluid levels. No tools are required to access daily service points, ensuring the maintenance is completed quickly – thereby reducing ownership costs.

- Maintenance-free parts

- Tool-free daily inspection

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

ROPS

A foldable rollover protection system reduces machine height and makes transport easier.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Engine

A highly efficient engine meets the latest worldwide emissions standards – and provides plenty of power, too.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Combination version

Combination rollers are unique machines that utilise both a drum and pneumatic tyres, enabling vibratory compaction or a kneading effect. Two independent water sprinkling systems allow the use of different liquids.

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

Electronic drive lever

Enables smooth starts and stops. The control is integrated in the system as an intelligent function. This technical solution prevents unnecessary damage to the freshly placed asphalt and also helps less experienced operators succeed.

Customers can choose from two operating modes:

- Soft drive mode

- Hard drive mode

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

ACE Compaction

ACEforce

- Covers the spectrum of compaction in soil and aggregates

- Available information includes achieved compaction

- Continuous compaction measurement system

- System is integrated in multifunctional display

- Can measure compaction at any point on-site

- Absolute measurement system with evaluation of real material stiffness

ARX 2.1-2 / ARX 2-2 LIGHT TANDEM ROLLER SERIES

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!