ATR / ACR RAMMERS

You want your crews to MOVE when they get on the jobsite. Ammann Rammers help them do exactly that. Our rammers feature the best forward-movement in the industry. These machines cover a lot of ground … and they deliver high compaction power every step of the way.

They’re great for contractors – and for rental fleets.

In fact, rental customers have been known to request Ammann Rammers because of their low hand-arm vibration levels that improve operator comfort and lessen fatigue. The rammers’ precise weight balance helps the inexperienced perform like seasoned pros. And there are flexible fuel options: Both petrol and diesel engines are available. Low ownership costs are another plus. Machine life is extended through a protective casing and high-quality components. Daily maintenance is quick … no tools are needed. And air filters are self-cleaning.

Ready to learn more? Click on the product hotspots or the chat contact.

ATR / ACR RAMMERS

Ease of use

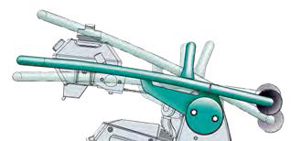

The optimal balance and user-friendly handle of the Ammann ATR Rammers make these machines a joy to work with.

The handle design creates sight lines to the rammer foot during the compaction process, providing confident movement around the jobsites. The open guide handle enables a secure grip from all sides, even when near obstacles.

Height adjustable

Every machine in the ATR line is equipped with a height adjustable handle, allowing operators of all sizes to choose from three height settings for maximum comfort throughout the shift. The handle also isolates vibration to protect the operator and reduce fatigue.

Low hand-arm vibration values

The operator is protected against hand-arm vibration syndrome, previously known as vibration “white finger,” even during long periods of use.

ATR / ACR RAMMERS

Variety of Shoes

ATR machines can be adjusted to match the jobsite application and the size of the operator.

The ATR 60 and ATR 68 include seven working widths, three working heights and an asymmetric foot that allows work along curbs and walls without the risk of tipping the machine.

The ACR 70 D features three working widths: 230 mm, 280 mm and 330 mm (9.1-11-13 in).

ATR / ACR RAMMERS

The balance and power you need

You need machines that deliver compaction power to the ground. And you need machines that can climb steep terrain on challenging jobsites.

ATR Rammers deliver on all fronts.

Pure compaction power

Exceptional design and engineering ensure the rammers’ powerful compaction punch is transferred to the surface, making the machines up to any challenges that might arise on jobsites.

Best-in-class machine balance

The rammers´ design and excellent engine position provides exceptional balance that prevents tipping and delivers a host of operator benefits, including effortless guidance and precise control. The balance also spurs the forward movement that boosts rammer performance and productivity - and ultimately leads to profitability.

Powerful engines

Each rammer features a reliable petrol or diesel engine that’s perfectly suited to its size. Efficient fuel consumption allows the operator to work up to four hours without refilling the gas tank machine to grant optimal power and long life.

ATR / ACR RAMMERS

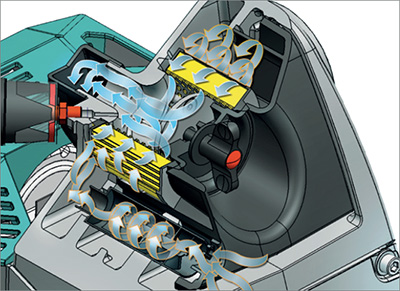

Air filtration

Improved air filtering extends the life expectancy of the rammer.

Long service life

Self-cleaning air filters reduce maintenance time. An optional cyclone pre-filter lowers pressure on the air filter, extending its life and cutting costs.

Double air filtration

The premium models feature the standard Ammann air filter together with the original filter from the engine. This double filtration system significantly extends the lifetime of the engine, keeping the machine productive for a longer period.

ATR / ACR RAMMERS

Robust & durable

Ammann Rammers are built to last. Taking a hit is not problem for the Ammann Rammers. High quality components and protective casings keep the machines running, even under the toughest conditions.

Designed for easy service

A well-thought-out design offers easy access to service points, so your crew can quickly complete the life-extending maintenance that keeps the machines up and running.

Tool-free daily inspection

Access to all daily inspection points is effortless and fluid indicators are easy to view. No tools are required to access daily service points, ensuring the maintenance is completed quickly.

ATR / ACR RAMMERS

Optimised gas throttle (Premium models only)

Optimised, multi-functional gas throttle eases the operation and assures a preserving handling for the engine to maximise it's lifetime.

0 – Stop position

The lever also automatically cuts off the fuel and shuts down the electric system.

1 – Idle speed

Fuel and electric system are turned on, engine can be started.

2 – Full speed

Machine is working and engine runs on optimal RPM.

ATR / ACR RAMMERS

Customised for your needs

Standard features provide operator safety and productivity. Options help you take the next step, enabling customisation that maximises productivity and cost efficiency on your jobsites.

Optional equipment

Hour meter

The optional working-hour meter helps you track usage and monitor maintenance needs. The meter is a great feature for rental companies, too.

Cyclone pre-filter

An optional cyclone pre-filter is available on ATR 60 and ATR 68 machines. The cyclone can help your filter last 5 times longer.

Transport wheels

Transport wheels allow you to effortlessly relocate the rammer on the jobsite without assistance of larger machines. The wheel wagon is simply clicked beneath the rammer and the machine is ready to roll. No time-consuming mounting is needed!