APF FORWARD VIBRATORY PLATES

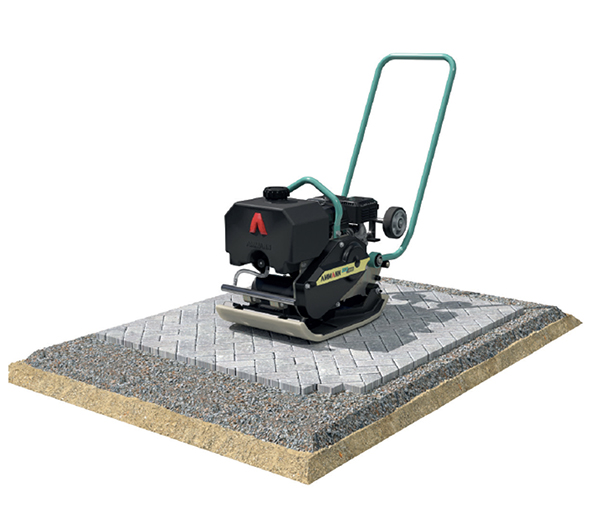

Ammann APF products are the lightest of all Ammann plate compactors, with weights ranging from 54 kg to 110 kg, providing a variety of sizes to fit the application and working space.

APF compactors that use either diesel or petrol are available, ensuring there is a product that meets the varied global emissions standards. It also enables crews to utilise whatever type of fuel is typically available on the jobsite.

Ammann plates are great fits for rental houses because of their extended service intervals – and because rental customers love their power, ease of operation, production and easy transport. Many of the plates are available with diesel or petrol engines, too.

Ready to learn more? Click on the product hotspots or the chat contact.

APF FORWARD VIBRATORY PLATES

Ease of use

Ammann APF plates are at the top of the class when it comes to operator safety and ergonomics. The plates offer the reliability and precise control necessary to adjust to changing jobsite challenges. Intuitive operation helps plate operators of all experience levels succeed.

Reduces unwanted vibration

Ammann plates lead the industry in lowest hand-arm vibration (HAV) levels. In fact, the levels are so minimal that the machines will remain in compliance with the strictest regulations for many years to come.

The reduced vibration values (below 2.5 m/sec2) result from the Z-buffer in the handle bar. This patented system enables long work shifts without health risk to the operator – or a need for documentation.

Highly manoeuvrable

The powerful forward movement of the plates boosts productivity and enables consistent results, even on steep grades. The base plate is designed to add forward-moving efficiency. The handle and grip on the machine frame help the operator manoeuvre the compactor in tight spaces.

APF FORWARD VIBRATORY PLATES

Easy transport

A central, easy-to-grip transport hook makes it simple to lift the plate while loading it into a vehicle or removing it from trenches. The plate is small enough to fit into a vehicle of any size.

The handle can be folded so it is flush with the machine and protected during transport.

APF FORWARD VIBRATORY PLATES

Optimum versatility

Quick-change options enhance versatility and ensure the machines are precisely matched for the jobsite.

The options include a rubber mat for working on paving stones and a water sprinkling system for asphalt applications.

Water sprinkling system

The tank and sprinkler are combined into a single unit that can be added or removed without any tools. Not even a single screw needs to be adjusted. The sprinklers provide comprehensive surface coverage and can be activated by simply turning a switch.

Toolless mountable rubber mat

This optional mat can be mounted in a few seconds, preparing the machine for work on paving stones and protecting the stones’ edges from cracking.

Transport wheels

The transport wheels can be dropped with a foot release. The wheels are durable and enable quick and easy movement around the jobsite.

Hour meter

The plates can be fitted with hour meters to help monitor maintenance needs.

APF FORWARD VIBRATORY PLATES

Vibratory system

The powerful vibratory system provides the productivity needed. It also features extended service intervals that reduce the cost of ownership and make Ammann plates more environmentally friendly, too.

Large exciter unit

Boosts power, speed, climbing ability and machine life.

APF FORWARD VIBRATORY PLATES

Robust design

Plate compactors face many challenges on jobsites – including materials that are difficult to compact, long working hours and continuously supplying the powerful vibration required to provide productivity. Ammann plates are built to meet these daily challenges. Their durability ensures success on the current jobsite – and those that follow, too.

Base plate

All Ammann forward-moving machines are equipped with base plates made from high-resistant steel. In addition, APF base plates are manufactured with no bended metal and no welded parts, so there are no weak spots.

The design further boosts machine life. The base plates feature thicker protection in the rear, where the most wear occurs.

The smart design and use of wear-resistant steel are so effective that base plate service is not required during the life of a machine that operates under typical working conditions.

APF FORWARD VIBRATORY PLATES

Productive all around

Ammann APF plates are great all-around machines, providing the solutions to work on every kind of jobsite where compaction is required. Their small size and productivity make them a valuable addition to every machine fleet.

Reliable power

The APF line is powered by reliable and efficient Honda or Vanguard petrol engines.

The APF 20/50 is available with a petrol or a Hatz diesel engine, which performs well in high altitudes and enables the use of a single fuel type on many jobsites.

The sturdy protection frame on all engines prevents damage during operation or transport, and ultimately extends plate life.

APF FORWARD VIBRATORY PLATES

Quick fitting paving pad

Toolless mountable rubber mat

Ammann APF plates excel when working with paving stones. Each machine can be equipped with a rubber mat that prevents the stones from being scratched or cracked.

No tools are required to mount or remove the mat, enabling quick switches between applications.

APF FORWARD VIBRATORY PLATES

Quick fitting water tank

Toolless mountable water tank

When working with bituminous materials, the APF plate can be equipped with a water tank and sprinkling system. The add-on tank can be quickly mounted on the machine – no tools required.

Refilling is easy, too. Simply remove the tank and carry it to the nearest water source.

APF FORWARD VIBRATORY PLATES

ServiceLink

Delivering the Data that Matters!

Ammann ServiceLink is a digital data management tool that provides customers with the information they want the most: machine location, battery status and operating hours. Data transfer is automatic thanks to new hardware, and access to the information is only a click away.

Manage your equipment – anytime, anywhere – with Ammann ServiceLink. This comprehensive fleet system provides key data for light compaction equipment, heavy compaction machines and asphalt pavers. You can choose which machines to track.

Highlights

- Supplies machine location, operating hours, battery status

- Provides one-click access to data

- Reliably transmits data from machines, no matter where they are

- Compatible with all machines produced by Ammann or other manufacturers

- Streamlines fleet upgrades (retrofit option)

- Easy to install

The hardware is easy to add as a retrofit

Simply attach the TCU and the battery to the machine. The TCU is activated when plugged into the battery. That’s it!